Barrel Engine History

Internal combustion engines have been around for a long time. The basic components of the engine are well known and include the engine block, cylinder head, cylinders, pistons, valves, crankshaft and camshaft. The cylinder heads, cylinders and tops of the pistons typically form combustion chambers into which fuel and air are introduced so that combustion takes place. Useful work is generated from the hot, gaseous products of combustion acting directly on the top or crown surface of the piston. Generally, reciprocating linear motion of the pistons within the cylinders is transferred to rotary motion of a crankshaft via connecting rods. One common internal combustion engine is known as an Otto-type internal combustion engine and employs a four-stroke cycle in which power is derived from the combustion process over four separate pistons movements (strokes): intake stroke, compression stroke, expansion (power) stroke, and exhaust stroke.

In traditional Otto-type automotive engine applications, the cylinders are typically stationary and are typically arranged in one of three ways: (1) a single row (in line) with the centerlines of the cylinders commonly vertically oriented; (2) a double row with the centerlines of opposite cylinders converging in a V (V-engine); or (3) two horizontal, opposed rows (opposed or pancake engine). Two additional Otto-type cylinder configurations were also experimented with, primarily between 1900 and 1950, and include (1) a radial configuration where the cylinder axes are arranged like spokes of a wheel with the lower rod ends mounted on a common crankshaft journal, and (2) a barrel configuration with cylinder axes arranged parallel around the central longitudinal axis of the engine. Barrel configurations generally include a stationary cylinder bank and the power is transferred to the crankshaft in one of three ways (1) with the lower ends of the connecting rods connected to a gear arrangement, (2) with the lower ends of the crankshaft connected to a wobble plate, and (3) with the lower ends of the rods pushing a cam surface.

A subclass of barrel engines are those with a rotating cylinder bank and such engines generally come in one of three configurations: (1) a two or four-cycle arrangement in which the rotating cylinder bank drives an angled thrust plate from which power is taken off as shown by way of example in U.S. Pat. Nos. 980,491; 1,345,808; 2,382,280 and 4,779,579; (2) a two-cycle arrangement in which a pair of rotating cylinder banks share a common cylinder head unit and in which the outer rod ends each drive an angled thrust plate as shown by way of example in U.S. Pat. Nos. 968,969; 1,255,664 and 1,779,032; and (3) a two-cycle arrangement in which a pair of rotating cylinder banks share a common piston and in which a pair cylinder head units are provided at each end thereof as shown by way of example in U.S. Pat. Nos. 3,830,208 and 5,103,778. It is believed, both radial and barrel engines, in particular, fell out of favor after World War II.

Beginning in the early part of the twentieth century, the conventional Otto-type reciprocating engine began to assume dominance as the most practical approach, even though it was recognized that the thermodynamic efficiency of the engine was such that about two-thirds of the energy developed through the combustion of the fuel was wasted. That is, roughly ⅓ of the fuel energy is delivered to the crankshaft as useful work, ⅓ is lost in waste heat through the cylinder walls, heads and pistons, and ⅓ is lost out of the exhaust.

The Wankel engine, which is also known as a rotary engine, is denoted as such because it utilizes a single triangular rotating piston which forms combustion chambers as it rotates within a stationary figure eight-shaped “cylinder”. The Wankel engine does not employ connecting rods as the rotating piston is linked directly to the crankshaft. The Wankel engine is also a four-stroke cycle engine, and while it has several advantages over the Otto-type engine, it produces higher emissions, has a shorter lifespan, and lacks torque at low speeds, which leads to greater fuel consumption.

The Rotodyne belongs to the subclass of barrel engines having a rotating cylinder bank. It is because of the rotational dynamics of the cylinder bank to the thrust or torque plate that give the Rotodyne it’s unique efficiency advantage compared to traditional stationary cylinders. Using various design orientations, relationships, positions, tilts and/or offsets of the rotating cylinders and thrust plate to which the pistons are connected, a dwell can be obtained where the piston remains substantially stationary with respect to the corresponding cylinder when transitioning from a compression stroke to a power stroke and/or control the speed of the piston during various portions of the cycle. Piston dwell is synonymous with Constant Volume Combustion (CVC) which is the textbook ideal combustion cycle heretofore impossible to achieve in a multi-cylinder 4-cycle combustion engine.

Constant Volume Combustion

The following theoretical study on Constant Volume Combustion was conducted in 2010-11 and while the author was unaware of any engine configuration to achieve the results, it’s almost as if it was written to further incentivize the development of the Rotodyne Engine.

Click to download the Constant Volume Combustion Study.

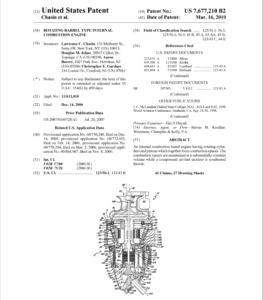

Rotodyne Engine’s Pioneering Patent Claim for Constant Volume Combustion

US Patent 7,677,210 is a pioneering patent on the discovery of controlling the piston dwell within a barrel type ICE. In particular claim 36 reads:

- A method of combusting fuel in an internal combustion engine having a rotating barrel-type cylinder bank configuration in which a piston moves within a cylinder, wherein the piston is operatively connected so as to rotate an output shaft, the method comprising the steps of:

- Moving the piston upward in the cylinder while the cylinder bank rotates during a compression stroke,

- Causing the piston to dwell near a top of the cylinder while the cylinder bank rotates while combusting substantially all of an air-fuel mixture, and

- Moving the piston downward in the cylinder while the cylinder bank rotates during a power stroke.

Click to Download US 7,677,210

Rotodyne Engine Development, LLC is now executing a distributed engine development strategy to partner with independent engine builder(s) to build and test a prototype of the revolutionary Rotodyne Engine, in order to then sell and/or license the technology under US Patent 7,677,210, which is the pioneering patent for constant volume combustion. All engine builder participants will receive a share of the profits and proceeds from all sales and licensing.

The Rotodyne Engine is set to disrupt the $500B standby generator market. It is the first and most practical multi-cylinder engine to employ the textbook constant volume combustion cycle. Other markets and applications worldwide provide further incentive.

Interested parties should contact us.